From 1942 production of the Me 109 Gustav took place at three main plants - Erla-Maschinenwerke in Leipzig, Wiener Neustädter Flugzeugwerke and Messerschmitt GmbH in Regensburg – and ran to a total of 16 series in 82 different designs. A rationalisation 'programme' had become absolutely necessary as well over 1,000 changes had been incorporated into the drawings. (quoted in Schmoll, 'Me 109 - Produktion und Einsatz') As a result major difficulties had arisen during repairs and the replacement of parts. In addition to the new DB engines with their larger superchargers and power boosting (the 'stop-gap' AS and the 605 D) a range of actions were introduced to improve 'commonality'. At the same time changes to the fuselage structure were introduced primarily to reduce drag and increase speed; eg the engine cowl covers were thickened by some 70 mm which enabled the elimination of the typical MG cowl ‘bulges’, the canopy was streamlined aerodynamically and pilot visibility improved (simplified canopy framing and mountings). Increased stability in the takeoff and landing runs was possible through bigger wheels, a lengthened tail wheel and a larger fin and rudder, the so-called ‘aufgestocktes Seitenleitwerk’. And so on.

Conceived as part of this 'programme', the G-10 was a 'new' light, fast fighter, powered by the DB 605 D adapted for B4 fuel with MW 50 power boosting. (Subsequent versions used C-3 fuel with MW 50). The Methanol/Water Sondernotleistung (special emergency power) injection was an aid to more effective combustion or 'wet' power. Author Schmoll states that the G-10 was the "..fastest variant of the Bf 109-series to see service, capable of 700 km/h at 7,500 m.." Intended to enter series production alongside the K-4 - bringing the Gustav-series up to K-series standard - deliveries of the G-10 actually started later than the K-4.

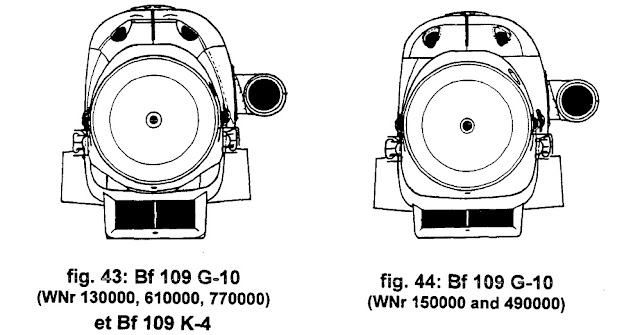

Distinguishing features include the refined 'elliptical' cowl shape over the MG 131s as seen on the G-6/AS. Independent of the engine variant fitted, Erla G-10 production (WNr in the 150-152 000 and 490-491 000 range) is (easily) identifiable by the asymetric cowl shape (designated 'Type 110' by Mermet) with the 'elliptical' or curved MG breech bulge only featuring on the starboard side. The 'Type 100' cowling with the Ballungen (elipse, plural) on both sides featured on WNF and Mtt Regensburg production and those airframes recycled from G-6s (eg, WNr. 130 000, 610 000 and 613 000). The DB 605 D featured a larger oil tank and a relocated oil filler hatch as one of the key ID features - due to the greater volume of oil (60 iso 45 litres) an oil cooler of larger surface area (wider and shallower) was present. Even though the small "chin" bulges were not a feature of the 'Type 110' cowl or required by the DB 605 D engine, these are present on the 'Type 100' cowl - probably in an attempt to increase 'commonality' with other variants then in series production. (see diagram below, from Mermet, 'Bf 109 G-1 to K-4, a guide to engines and fittings')

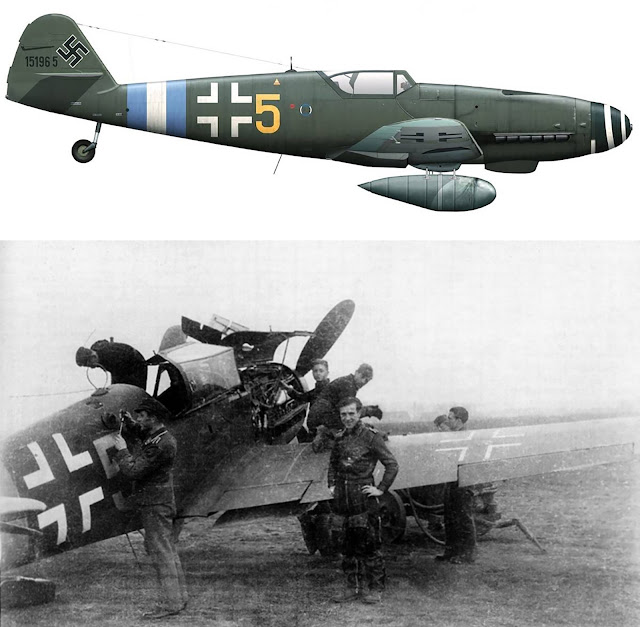

Below; late-war Erla Bf 109 G-10 in overall dark green as seen in service with I./JG 300. (Anders Hjortsberg artwork) A good view of the rectangular cowl section (just in front of the windscreen) being removed with what may be an Erla WNr. (?50719) visible.....

On the starboard side of the 'Type 110 cowl' the hatch for the cold weather starter is repositioned much higher up on the cowl (appears lower near the exhaust stack on the G-14). Other features of the G-10 include the tall tail with trim tabs and enlarged fairings on the wing to accomodate the bigger main wheels - and of course the 'Vollsichthaube', the 'clear vision' canopy minus the heavy framing. Note the absence of an antenna mast - replaced by the under-wing whip aerial - another 'streamlining' measure on late-war Bf 109 production.

There are really no hard and fast rules with late-war 109s of course - early Regensburg G-10 production featured the original G-6 wing with the smaller main wheels and upper wing 'tear-drop' bulges and according to some (eg Wolowski) early Erla G-10s - possibly as many as fifty examples - received the AS engine with the bigger deep radiators and lower cowling bumps. These were from the first production batch, WNr. 490 000. These may have been designated G-10/AS (see JfV Teil 13/IV pages 27 and 28). Erla referred to them as 'Bastard Flugzeuge'.

The concept of a G-10/AS usually provokes a comment or two. The 'true' 109-experts will deny that the Bf 109 G-10/AS even existed. Several units nonetheless reported Bf 109 G-10/AS machines in their loss returns - in particular JG 300 - and, as far as is known, mostly in the Erla 490 000 WerkNr. range..

17 Dec 44 - Lt. Köhler, Otto - 10./JG 300 Bf 109 G-10/ASM, WNr. 490291 'White 1', combat with P-51, 100%.

24 Dec 44 - Lt. Kampf, Werner - 10./JG 300 Bf 109 G-10/ASM WNr. 490299 ''white 11', combat bei Erfurt, 100%

(Some would say DB 605 AS powered Bf 109 G-10s were simply designated as Bf 109 G-10)

According to Mermet's first book around 4,500 G-10s were built, of which 3,500 were either re-cycled Gustav airframes, or Gustav airframes that received the 605 D engine while in production! Figures that proved to be wildly inaccurate...

Schmoll quotes the following figures for G-10 production;

Erla - 1,534 G-10 (November 44- Feb 45, including 916 G-10/R6 with the Patin PKS 12 Kurssteuerung 'automatic pilot')

Mtt Regensburg - 116 G-10 (October 44 -Jan 45)

WNF - approx 360 G-10/U4 (Mk 108 30mm cannon +MGs, only built by WNF during January -Feb 45)

A further 518 G-10s were constructed during March 1945 by Erla and WNF before production ended.

Below; Me 109 G-10/U4 of II./JG 52, WNr probably in the 611 000 range (WNF production) at Neubiberg after surrender. An enlargement from the negative via James V.Crow collection. Click for a full-screen view.

AZ 'Erla' Bf 109 G-10 by Jan Pavlik